In this week’s guest blog James Baker (Hereford Make CIC) offers his insights into setting up ‘open to all’ workshop spaces and invites you to support the crowd funding of their exciting project.

Intro

When faced with the aim of having workshops that are accessible for people to up skill-up, repair, make and have a business in, there are several challenges to face. My name is James Baker and I have set up and am setting up more workshop spaces that are accessible to professionals and public alike to help with wood work, blacksmithing and metal work. I wish to share my thought on setting up such workshops and what I have learnt.

Research and Data Capture

One of the key parts of having workshops is to know who to make the workshops for. There are several groups that can be identified into the medium, i.e. wood work, ceramics, etc., and the user groups, NEET’s (a young person who is “Not in Education, Employment, or Training”), professionals, the general public, etc., and then what their needs are. The research is also on going and once you have something to show people then other groups will ask for help. Once word got out about our workshops for blacksmiths, wood workers and metal workers we were, and still are getting, requests from ceramists, media and textile workers asking for a workshop space as well.

One of the key methods for keeping up to date research is to data capture what your workshops are doing. This can be a drain on your users but you need this evidence to help make informed decision on how to run your workshops and give context on how much good your workshops are doing. An example of our data capture includes information about our users’ demographics, environmental practice, economic activity, artistic understanding and skill base.

We have to ask these questions so that we know we are helping people in the local area, achieving our aim of recycling materials, enabling a place where people can have their own business, have a place they can develop their creativity and develop their skills.

Meeting the needs

Based on the research and what you aim to do with your workshops you then have 3 types of workshops:

-Repairs

-Skill development

-Business and manufacture

Repairs are the easiest to create because they are relatively cheap, are not doing a huge amount of work and can be completed just by professionals donating their time and equipment. They are useful for environmental impact due to the repair and recycling materials. A good example of repair workshops, in my opinion based on my experiences of Malvern’s one, are the repair cafes (http://repaircafe.org).

They are pleasant environments to work in and include people who have a broad range of skills and meet often enough to meet the needs of the community.

Skill development workshops can do repairs but in addition teach people and can be informal. How do make and develop transferable skills? This is something particularly useful if you are trying to help counter NEET’s demographic, long term unemployed and groups that need help to get employment. However, this is more difficult due to the resources needed.

Typically you’ll need hand tools a building with b1 planning should be sufficient. This is needed due to the standard of equipment the workshop should hold and staff are needed to teach and maintain the equipment. You are looking at equipment assets at about £5,000 as a guild line before rent. Look to have skills that can be pursued within the local educational establishments. An example of this style of workshop would be http://www.thelivingfurnitureproject.org.uk.

Business and manufacture can do both skill development and repairs. This is good for economic development because it enables expensive businesses to start at an affordable rate but is the most difficult. The difficulty is similar to the difference between the repair to skill development but doubled because the requirements of the users is more demanding.

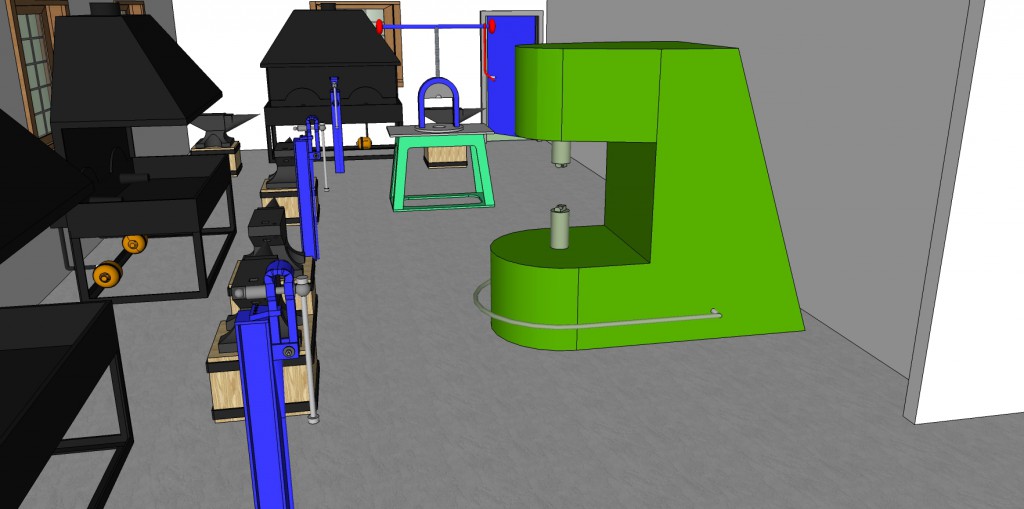

With these workshops you ideally need to have a lot of specialist equipment to enable process efficiency and flexibility of manufacture; i.e. the option to work large rather than be forced to work small. Where as the other workshops had a few people making a living, through part time support of teaching, all the users are using these workshops to make a living. So the equipment needs to fulfil this aim. As an idea of the differences, you are likely to need b2 planning permission, about £50,000 of equipment and some support staff to help both in the making and support their businesses.

Materials and Equipment

Working out what materials you will use and will not use is quite important because it will inform how to lay out your workshop, storage of those materials, correct disposal of the waste, any conflicting issues (i.e. keep the wood work away from the forge fires) that need to be managed.

There’s also health and safety protocol and environmental impact that all go to inform equipment decisions. For example, if you are a ceramic workshop and choose to work porcelain clay you need a kiln that fires at higher temperatures. You’ll also need to look at how to run your workshops and bring in to focus where you stand on certain issues. For example do you choose to only work natural woods because the waste is more environmentally safe, the material can be recycled easily and is a carbon neutral material compared to the cheaper, more consistent and easier accessed man made woods? Do you only repair natural wood items or all wooden items? These choices will crop up and then do you force you opinion on your users?

My advice on this is first be clear on what you want your workshops to do then make it as easy as is practicable for your users to make the choice. Some examples of how this can be done can include having a list of ethically sourced timber suppliers, choose to upcycle a damaged object and not just repair it, design objects to be made from materials that enable the object to have a long work life, have materials that can be used again if the object is broken and design for the object to have a disposable component to increase the work life.

Once you know what materials you are working with you then have to get the tools to work them. Getting equipment, particularly on a budget, can lead to some difficult choices, new or second hand, extra features or basic model are the main ones.

On the topic of new or second hand the advantages of new equipment being warranty, energy efficient and supported (i.e. you can get the parts if it breaks or consumable parts are available) compared to the cheaper, often more accessible and increasing the work life of second hand equipment. It’s a difficult position to be in. On this I would say look at what you do the most of in any given process and prioritise the things you do most with new equipment and work back from there.

New equipment is particularly important for developing skills with NEET’s and long term unemployed due to a lack of self-esteem and confidence. New equipment lets them see results faster and helps build on these problems more efficiently. If you are expecting a large number of users you can help control the quality of tools by buying new and save through bulk buying and negotiating the price. Lastly efficiency is a crucial factor for start up businesses because they have to establish their practice, which is difficult and they need any advantage they can get.

When choosing between extra features or basic model the question becomes how much to invest in one piece of equipment’s features specialising in one process? What you intend to make is the key factor here. If you are having set pieces to be made by a fixed number of processes the extra cost normally is justifiable. If you are after flexibility having multiple basic tools is the best start and then if you find certain processes being favoured then you can re-evaluate.

An important factor is how much space do you have? Having a small multi-process machine with lots of features might be the most appropriate but if it breaks you will be stuck. With skill developments, lots of basic equipment is favourable, so that there are more skills to learn. Your or your users capability to design and make will inform how best to make these choices. Often you can trade in an old model to a supplier and get a new one helping take the pressure off getting it right first time.

Health and Safety

Workshop organisers have to look at the materials and processes and look at the risk to their users based on the health and safety reports. Risk is measured by looking at the chance of the risk happening and the severity of that risk. Then applying those control measure to make them safe. This is why you can find lots of textile and print workshops because they are safe and cheap. However if something goes wrong there is a person that is responsible and that person can go to prison. This often puts people off having larger more efficient equipment which is why repair and skill based workshops are often use basic equipment.

Adding another layer of complexity is the option to be accessible to the public, which changes both the control measure standards and increase the overall risk of an accident. These 3 factors is what drives people away from managing and setting up substantial workshops in ‘dangerous’ mediums and causes the cost of these workshops to sky rocket.

This makes having public accessible workshops with industrial standard equipment for blacksmith, wood work and metal work very rare. The only more dangerous process we could add to this is metal casting. The idea of having workshops accessible for the public to skill-up, repair, make and have a business in, is high risk and this is why I believe I am the only person currently creating this standard of workshop.

Funding and Sustainability

The research you have done will help inform where to go for funding and if your workshops are sustainable. Funding bodies need to see evidence and there are different funding bodies that want to see different evidences. Funding bodies generally have specific aims, examples include city councils want to see their denizens happier with more opportunities and banks want to see you make the most money to pay them back, so gathering the evidence you have and presenting it to address their aims is key. You need to see if they will fund you and will give you funding for what you need.

Evidence breaks down into hard evidence and soft evidence and hard evidence is always the better to use but is not always available. Hard evidence removes any uncertainty and examples include, but not limited to, contracts, statistics and cash from appropriate sources. Soft evidence gives you an idea and is easier to get a hold of but it is not definitive. Soft evidence examples include, but not limited to, Facebook likes, purely verbal comments and letters of interest.

The evidence you gather can help get you the money you need and show the money people invest in your workshops is safe. Something that can add to a portfolio of evidence is a similar workshop that is successful. Remember the organisation needs to be sustainable not the project so if you want to be part of a larger group that pays for you and it works for all involved that can be sustainable. Normally the users need to pay to use the workshop. So you’ll need an idea of cost per user and how many paying users are need to keep the workshop going. You can often find funding to help your users use your workshops. This is often where the workshop sustainability can fail and so will the project.

Conclusion

I hope this article has given some insight into the problems, and possible solutions, of having workshops for all. I feel I have show that workshops are a flexible solution to a multitude of problems we currently face as a society. There are more aspects and views on workshops, for example legal structures, fab labs vs. workshops, supporting your local makers amongst others, but now I ask for you to help my community by donating to make the workshops our region needs so desperately and which address several social problems in the area, by going here: http://www.buzzbnk.org/herefordmake. Anyone can do it. The smallest contribution, which is accepted with gratitude, is only £2. Hereford Make C.I.C. is aiming to raise £10,000 in total for our community workshops. This is broken down into to groups of £5,000 so please give even though it might say we have hit our £5,000 target.

This will help support new workshops by proving that the solution does work. You can show local funding bodies, in your area, that it really is worth having one.

Thank you for your time

James Baker

Managing Director of Hereford Make C.I.C.

Image credits: All images courtesy of James Baker

Connect